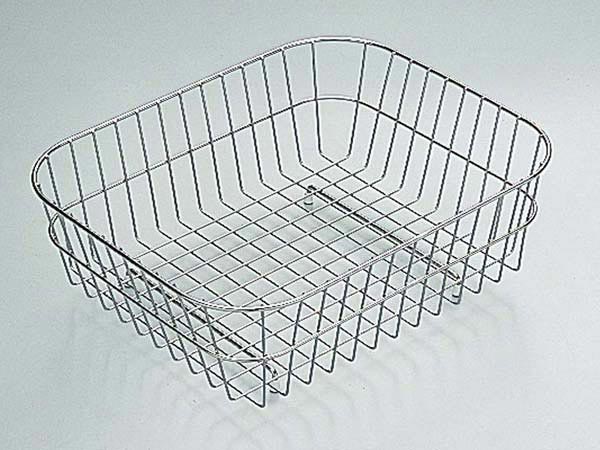

Type: Stainless steel wire

Applications:

- Mesh of high resistance against humidity and against very high or very low temperatures, as following : nets for refrigerators, washing machines, sinks, rotating mechanisms for cabinets, shelves for cabinets, libraries etc, bathroom accessories, baskets and trolleys for super-market, cages for pets, woven mesh, etc

- bicycle and umbrella spokes

- binding of bricks and ceramics during their production inside the furnaces of the brick industry

- bindings where clear surface and high anti-corrosion protection is needed

- decorations

- fences with high anti-corrosion resistance

- conveyor belts

- wire nails, pins, staples of high resistance

- wire ropes of high resistance

- razor wires of high resistance

- springs of high resistance

Quality: The most wide spread grade is the AISI 304 L. The most basic grades are the following: 201, 204Cu, 304, 304L, 310, 310S, 316, 316L, 321, 430

Diameters: From 0.10 mm up to 24.00 mm

Packing:a) in bundles of 50 - 500 kg (unbinding from the top), b) in straight cut lengths of 1 - 6 m

| STAINLESS STEEL WIRE | ||||||||

|---|---|---|---|---|---|---|---|---|

| GRADE AISI | Carbon C | Manganese Mn | Silicon Si | Phosphorus P | Sulphur S | Nickel Ni | Chromium Cr | |

| 201 | 0.15 | 5.50-7.50 | 1.00 | 0.060 | 0.030 | 3.50-5.50 | 16.00-18.00 | ANTI-MAGNETIC |

| 204 Cu | 0.08 | 6.50-8.50 | 1.50 | 0.06 | 0.030 | 1.50-2.00 | 16.00-18.00 | ANTI-MAGNETIC |

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 8.00-10.50 | 18.00-20.00 | ANTI-MAGNETIC |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 8.00-10.50 | 18.00-20.00 | ANTI-MAGNETIC |

| 310 | 0.25 | 2.00 | 1.50 | 0.045 | 0.030 | 19.00-22.00 | 24.00-26.00 | ANTI-MAGNETIC |

| 310S | 0.15 | 2.00 | 1.50 | 0.045 | 0.030 | 19.00-22.00 | 24.00-26.00 | ANTI-MAGNETIC |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 10.00-14.00 | 16.00-18.00 | ANTI-MAGNETIC |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 10.00-14.00 | 16.00-18.00 | ANTI-MAGNETIC |

| 321 | 0.05 | 1.50 | 1.00 | 0.040 | 0.015 | 9.00-11.50 | 17.50-18.00 | ANTI-MAGNETIC |

| 430 | 0.12 | 1.50 | 1.00 | 0.040 | 0.030 | 0.30 | 16.00-18.00 | MAGNETIC |

Comment No 2 : Chromium declares the corrosion resistance of the wire. The higher the chromium is, the higher anti-corrosion protection the wire has.

Comment No 3 : Nickel is linked with several properties of the wire. The higher the nickel is, then, a) the wire has better formability, b) has better weldability, c) the toughness is bigger, d) the anti-corrosion resistance is bigger, e) has better luster and f) behaves better at high temperatures.